Eliminate Unwanted Noise and Lock it Away

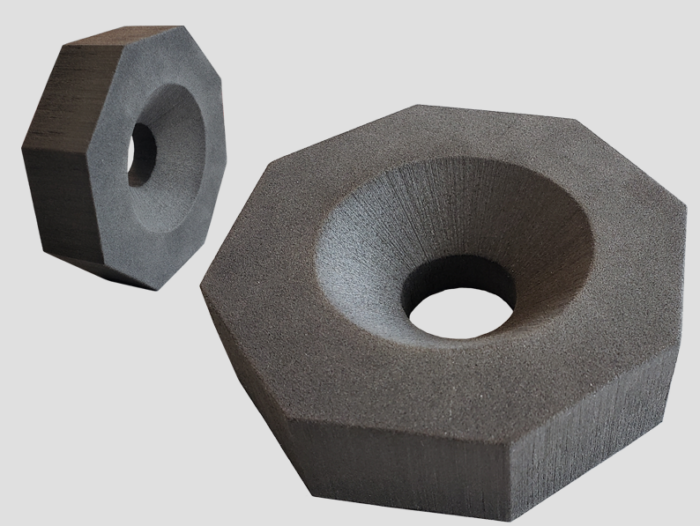

Able to absorb sound energy in everything from computers to engine components, Sound Absorption solutions by Blachford are the ideal way to remove excess noise from any product. Available in a wide array of thicknesses and types, these solutions can be custom molded to address any application.

Eliminate Unwanted Noise and Lock it Away

Able to absorb sound energy in everything from computers to engine components, Sound Absorption solutions by Blachford are the ideal way to remove excess noise from any product. Available in a wide array of thicknesses and types, these solutions can be custom molded to address any application.

Customers Who Trust Blachford Acoustics Group

“Blachford eliminated SKUs. Across product families, the reduction of one SKU is a $10k savings. Blachford eliminated 14 SKUs.”

– Noise Control Research Engineer – Construction Equipment Manufacturer

“The first project with Blachford, it was a definite quality improvement, and it was over a million dollar yearly cost savings for just the purchase parts themselves. We went from 28 (SKU) parts to 14.”

– Design Engineer – Heavy Equipment Manufacturer

“Noise is important to brand image. It is one of the top factors along with driveability and reliability. Acoustics – it’s a 4 out of 5, it might even be a 5 in importance projecting the image, the brand, and the quality that we want projected to the market.”

– Design Engineer – Truck Manufacturer

“Our ten-fold growth prior to our acquisition was expedited by our working relationship with Blachford.”

– Design Engineer

“For our shareholders, we have to produce a product at the lowest cost, at the right level of quality and sell it at the highest price we can. We look for suppliers who can help us do that. Blachford helps us do that.”

– Global Procurement Manager – Construction Equipment Manufacturer

“When a company does a spec, boundary conditions like humidity that day, temperature, that all matters. ASPM national or international spec. We try to verify where we can, but we don’t even have the equipment they have. We trust their specifications. Blachford brings innovative ideas, processes, materials, and offerings we value.”

– Design Engineer – Truck Manufacturer

“Then, bringing them in at the beginning with our new product design, it probably saved 6-12 months of development. We didn’t just wa nt the spec sheet value. We wanted customers to get in the machine and experience the difference.”

– Design Engineer – Heavy Equipment Manufacturer

“If we have an acoustics issue, we will reach out to Blachford since they are the experts. It saves us money because we do not have to keep an acoustic expert on site with an annual salary, with benefits, of $125K.”

– Design Engineer – Truck Manufacturer

“As a mechanical engineer, we make stuff that is practical and affordable and Blachford’s materials routinely help me reach these goals.”

– Design Engineer

“We [purchasing department] reported savings of $100k annually from moving to the die-cut solution using Blachford.”

– Design Engineer – Truck Manufacturer

Customers Who Trust Blachford Acoustics Group

“Blachford eliminated SKUs. Across product families, the reduction of one SKU is a $10k savings. Blachford eliminated 14 SKUs.”

– Noise Control Research Engineer – Construction Equipment Manufacturer

“The first project with Blachford, it was a definite quality improvement, and it was over a million dollar yearly cost savings for just the purchase parts themselves. We went from 28 (SKU) parts to 14.”

– Design Engineer – Heavy Equipment Manufacturer

“Noise is important to brand image. It is one of the top factors along with driveability and reliability. Acoustics – it’s a 4 out of 5, it might even be a 5 in importance projecting the image, the brand, and the quality that we want projected to the market.”

– Design Engineer – Truck Manufacturer

“Our ten-fold growth prior to our acquisition was expedited by our working relationship with Blachford.”

– Design Engineer

“For our shareholders, we have to produce a product at the lowest cost, at the right level of quality and sell it at the highest price we can. We look for suppliers who can help us do that. Blachford helps us do that.”

– Global Procurement Manager – Construction Equipment Manufacturer

“When a company does a spec, boundary conditions like humidity that day, temperature, that all matters. ASPM national or international spec. We try to verify where we can, but we don’t even have the equipment they have. We trust their specifications. Blachford brings innovative ideas, processes, materials, and offerings we value.”

– Design Engineer – Truck Manufacturer

“Then, bringing them in at the beginning with our new product design, it probably saved 6-12 months of development. We didn’t just wa nt the spec sheet value. We wanted customers to get in the machine and experience the difference.”

– Design Engineer – Heavy Equipment Manufacturer

“If we have an acoustics issue, we will reach out to Blachford since they are the experts. It saves us money because we do not have to keep an acoustic expert on site with an annual salary, with benefits, of $125K.”

– Design Engineer – Truck Manufacturer

“As a mechanical engineer, we make stuff that is practical and affordable and Blachford’s materials routinely help me reach these goals.”

– Design Engineer

“We [purchasing department] reported savings of $100k annually from moving to the die-cut solution using Blachford.”

– Design Engineer – Truck Manufacturer

It’s Easy to Get Started

STEP 1:

COMPLETE OUR GET STARTED FORM

Give us some basic information about your sound, vibration or thermal reduction goals.

STEP 2:

COLLABORATE WITH OUR EXPERTS

Our team of engineers will work with you to uncover all issues and identify possible solutions.